A business process is a collection of related activities that produce an artifact ready to be used by another process, a service, or a client. Business processes occur at all levels of every organization.

The most effective processes are the simple processes. Often time, business processes start simple and uncomplicated. However, as organizations grow these simple either morph into new processes or interface with new processes to produce the same results. You can see how processes can quickly easily become intertwined and complicate. Enter Business Process Improvement and Continuous Improvement.

Process improvement involves the business practice of identifying, analyzing and improving existing business processes to optimize performance, meet best practice standards or simply improve quality and the user experience for customers and end-users.

Process improvement can have several different names such as business process management (BPM), business process improvement (BPI), business process re-engineering, continual improvement process (CIP), to name a few. Regardless of the nomenclature, they all pursue the same goal: to minimize errors, reduce waste, improve productivity and streamline efficiency.

Process Improvement Techniques

There are several different methodologies designed to help your organization tackle process improvement. Each aims to help your business identify process issues, fix them and analyze the success or failure of those changes.

Despite that common goal, each methodology suits a different need. Some frameworks focus on lean process improvement techniques; others focus on getting your company culture in the right place for process improvement. There are also methodologies that help companies visually map out process workflows.

Kaizen promotes continuous improvement with a strong emphasis on lean and agile practices. Kaizen focuses on improving quality, productivity and efficiency through small shifts in daily work or corporate culture to foster an environment that doesn’t punish errors or mistakes, but instead works to prevent them from happening again.

the 5S model is part of the Kaizen and Lean methodologies and it stands for five main steps: sort, straighten, shine, standardize and sustain. The 5S model helps bring more consistency to process improvement and can standardize process improvement.

PDCA (plan, do, check and act) is also part of the Kaizen methodology. It helps organizations be more efficient when identifying processes that need improvement. You first identify the problem (plan), create and implement a solution (do), evaluate data for effectiveness (check) then document the final results and implement the plan if it’s successful (act).

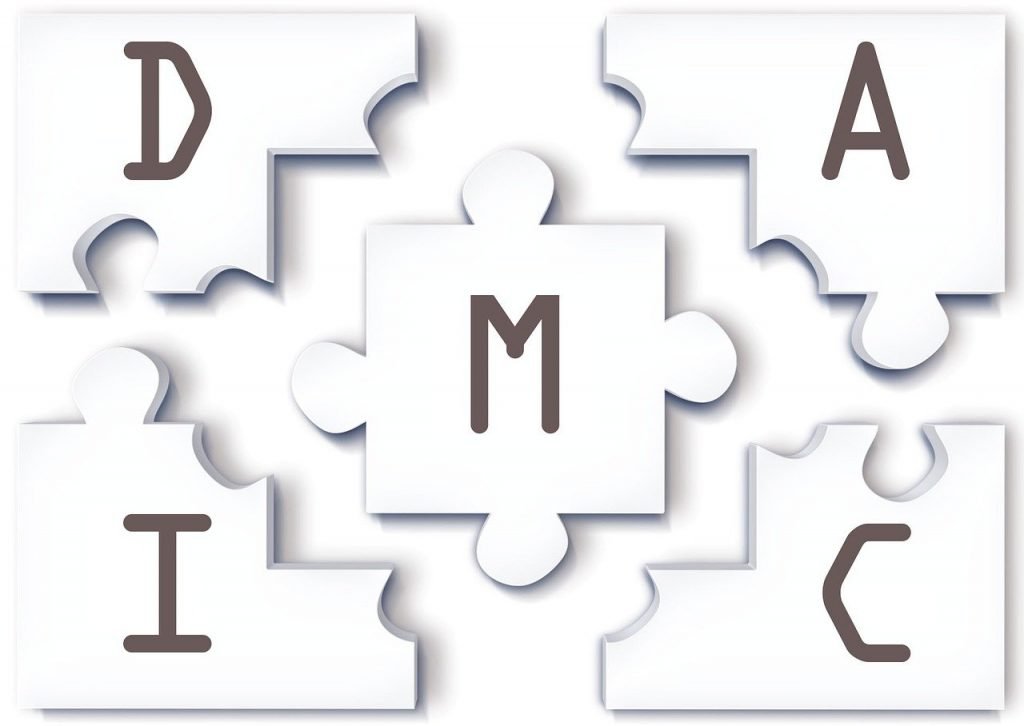

Six Sigma is a popular process improvement methodology that pulls workers up through ranks classified using karate belts. You start as a green belt and learn your way up to a black belt. Six Sigma involves two ways to break down process improvement through specific steps. These steps include define, measure, analyze, improve and control (DMAIC) and define, measure, analyze, design and verify (DMADV).

Cause and Effect Analysis is another tool born from Six Sigma. It involves using a diagraming method to fix problems by identifying the problem, discovering road blocks and pinpointing why the process isn’t working.

SIPOC Analysis uses a diagram format that falls under the Six Sigma methodology, SIPOC analysis happens during the “measure” stage of DMAIC or DMADV. SIPOC helps organizations define and establish a process improvement project as well as identify requirements and necessary elements before starting.

Value Stream Mapping (VSM) helps organizations visually represent customer’s perceptions of a business process, which helps identify the value of a product, process or service to the organization. Similar to other methodologies, it’s highly focused on eliminating waste, redundancy and being as lean as possible.

Total Quality Management (TQM): Focuses on cultivating long-term success through customer satisfaction, TQM helps organizations get the entire company on board with continuous process improvement. It’s a methodology that empowers workers by fostering a culture where employees aren’t afraid to make mistakes and are driven towards a shared business goal.

Kanban is a tool for process workflow visualization that gets business units, leadership and employees on the same page for process improvement. It’s another methodology that incorporates and encourages lean process improvement. Process mapping: Another workflow visualization that helps companies map out a plan for process improvement is process mapping. It can also be called a process flowchart, process chart, functional flowchart and process model. Ultimately, it’s the process of creating a flow diagram that delivers vital information about a process workflow from start to finish.

Examples of BPI Tools

Depending on the nature of your operation and the kinds of problems you’re attempting to solve, you’ll need to pick a right tool or a combination of these tools.

Remember, you can either use a hammer to fix all kinds of projects or select the right tool for the job.

-Max

Contact us for a free consultation and find out which tools are right for your improvement projects.